Nekukwezva kukuru mumhando dzakasiyana-siyana dzezvigadzirwa zvemaindasitiri, mhangura inoonekwa sechinhu chinoshandiswa zvakasiyana-siyana.

Mafoiri emhangura anogadzirwa nenzira chaiyo yekugadzira mukati mefoiri mill inosanganisira kutenderedza kunopisa nekutonhora.

Pamwe chete nearuminiyamu, mhangura inoshandiswa zvakanyanya muzvigadzirwa zvemaindasitiri sechinhu chinoshanduka-shanduka pakati pezvinhu zvesimbi zvisina feri. Kunyanya mumakore achangopfuura, kudiwa kwefoil yemhangura kwave kuchikwira zvakanyanya kune zvigadzirwa zvemagetsi zvinosanganisira nharembozha, makamera edhijitari, uye zvishandiso zveIT.

Kugadzirwa kwefoil

Mafoil emhangura matete anogadzirwa ne electrodeposition kana kuti kutenderedza. Pa electrodeposition, mhangura yepamusoro inofanira kunyungudutswa mu acid kuti igadzire electrolyte yemhangura. Iyi electrolyte solution inopombwa mumadhiramu akanyudzwa zvishoma, anotenderera anochajwa nemagetsi. Pamadhiramu aya pane firimu rakatetepa remhangura rinoiswa electrodeposition. Maitiro aya anozivikanwawo se plating.

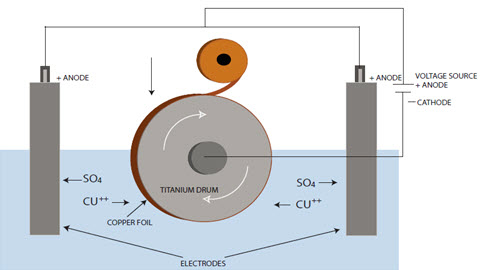

Mukugadzirwa kwemhangura ine electrode, foil yemhangura inoiswa padhiramu rinotenderera retitanium kubva kumhinduro yemhangura kwainobatana neDC voltage source. Cathode inonamirwa padhiramu uye anode inonyudzwa mu copper electrolyte solution. Kana simba remagetsi rikaiswa, copper inoiswa padhiramu painotenderera zvishoma nezvishoma. Pamusoro pemhangura kudivi redhiramu pakapfava nepo divi rakapesana rakakora. Kana dhiramu richimhanya zvishoma, copper inokora uye zvinopesana. Copper inokwezvwa uye inounganidzwa pamusoro pe cathode yedhiramu retitanium. Rutivi rwe matte nedhiramu rwe copper foil runopfuura nenzira dzakasiyana dzekurapa kuitira kuti copper ive yakakodzera kugadzirwa kwePCB. Kurapa kunowedzera kubatana pakati pe copper ne dielectric interlayer panguva ye copper clad lamination process. Imwe mukana wekurapa ndeyekushanda se anti-tarnish agents nekudzora oxidation ye copper.

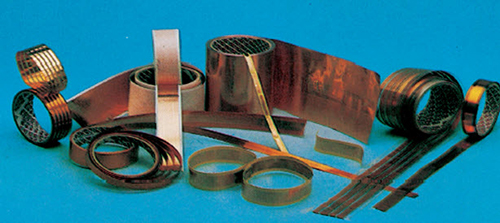

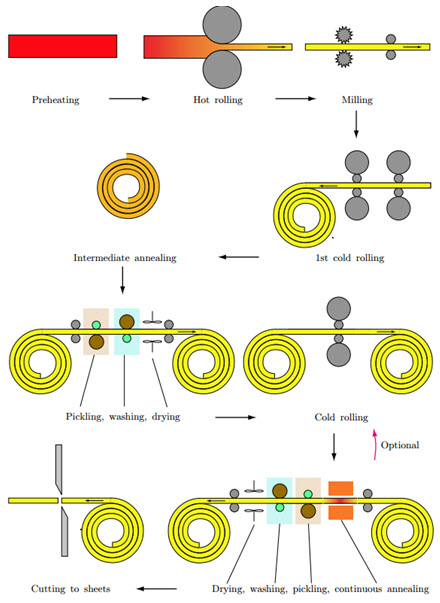

Mufananidzo 1:Maitiro Ekugadzira Mhangura Yakaiswa MumaelectrodeMufananidzo 2 unoratidza maitiro ekugadzira zvigadzirwa zvemhangura zvakamonerwa. Midziyo yekumonera yakakamurwa kuita mhando nhatu; dzinoti, mill dzinopisa, mill dzinotonhora, uye mill dzefoil.

Makoiri emafoiri matete anoumbwa uye anogadziriswa nemakemikari nemagetsi kusvika agadzirwa muchimiro chawo chekupedzisira. Ruzivo rwekutenderera kwemafoiri emhangura rwuri muMufananidzo 2. Bhokisi remhangura yakakandwa (zviyero zvingangoita: 5mx1mx130mm) rinopiswa kusvika 750°C. Zvadaro, rinopetwa richidzoserwa mumatanho akati wandei kusvika pa1/10 yeukobvu hwaro hwepakutanga. Kutonhora kusati kwatanga, makwande anobva pakupisa anobviswa nekugaya. Muchando, ukobvu hunoderedzwa kusvika pa4 mm uye machira anogadzirwa kuita macoil. Maitiro acho anodzorwa nenzira yekuti zvinhu zvinongoreba uye hazvichinji upamhi hwazvo. Sezvo machira asingakwanise kuumbwa zvakanyanya mumamiriro aya (chinhu chacho chakaoma zvakanyanya), anopiswa uye anopiswa kusvika pa550°C.

Nguva yekutumira: Nyamavhuvhu-13-2021