Indasitiri yezvinhu zvePCB yapedza nguva yakawanda ichigadzira zvinhu zvinopa kurasikirwa kwakaderera kwechiratidzo. Kune magadzirirwo ekumhanya kwakanyanya uye magadzirirwo efrequency yakakwira, kurasikirwa kuchaderedza daro rekupararira kwechiratidzo uye kunokanganisa masaini, uye kuchagadzira kutsauka kweimpedance kunogona kuonekwa mukuyera kweTDR. Sezvatinogadzira chero bhodhi redunhu rakadhindwa uye kugadzira macircuit anoshanda pamafrequencies akakwira, zvinogona kunge zvichikukwezva kusarudza mhangura yakapfava muzvigadziriso zvese zvaunogadzira.

Kunyange zvazvo chiri chokwadi kuti kukora kwemhangura kunowedzera kutsauka uye kurasikirwa kweimpedance, foil yako yemhangura inofanira kunge yakapfava zvakadii? Pane dzimwe nzira dziri nyore dzaungashandisa kukunda kurasikirwa pasina kusarudza mhangura yakapfava kwazvo pakugadzira kwega kwega? Tichatarisa pfungwa idzi muchinyorwa chino, pamwe nezvaungatsvaga kana ukatanga kutenga zvinhu zvePCB stackup.

Mhando dzePCB Copper Foil

Kazhinji kana tichitaura nezvemhangura pazvinhu zvePCB, hatitauri nezvemhando chaiyo yemhangura, tinongotaura nezvekuoma kwayo. Nzira dzakasiyana dzekuisa mhangura dzinogadzira mafirimu ane hunhu hwakasiyana hwekuoma, izvo zvinogona kuoneka zvakajeka mumufananidzo we scanning electron microscope (SEM). Kana uchizoshanda pama frequency akakwira (kazhinji 5 GHz WiFi kana kupfuura) kana nekumhanya kwakanyanya, saka teerera mhando yemhangura yakatsanangurwa mu datasheet yako yezvinhu.

Uyewo, iva nechokwadi chekuti unonzwisisa zvinorehwa neDk values mudhatabheti. Tarisa hurukuro iyi yepodcast naJohn Coonrod wekuRogers kuti udzidze zvakawanda nezveDk specifications. Tichifunga izvozvo, ngatitarisei mamwe marudzi akasiyana ePCB copper foil.

Yakaiswa mumagetsi

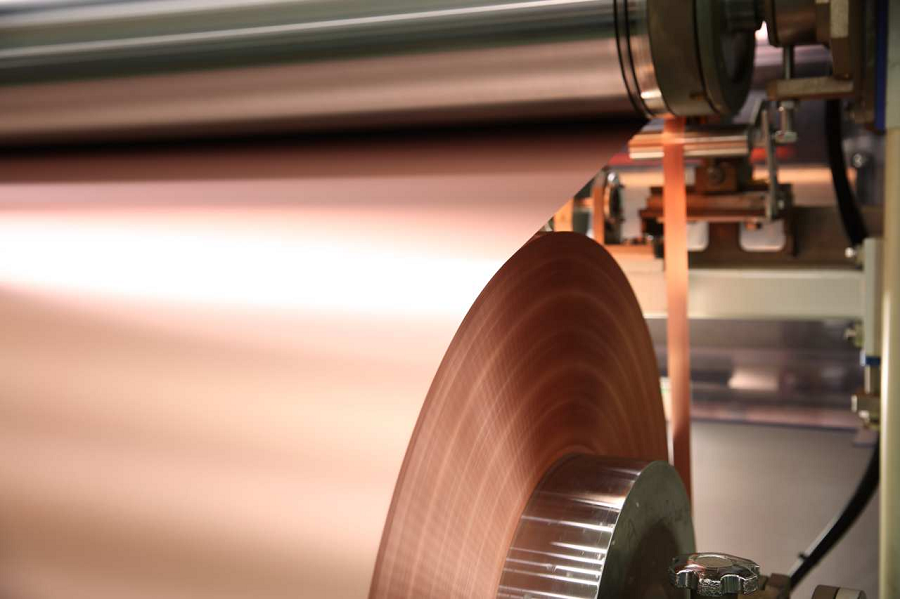

Mukuita uku, dhiramu rinotenderedzwa kuburikidza ne electrolytic solution, uye electrodeposition reaction inoshandiswa "kukudza" copper foil padhiramu. Sezvo dhiramu richitenderera, firimu re copper rinobuda rinoputirwa zvishoma nezvishoma pa roller, zvichipa jira re copper rinoenderera mberi rinogona kuzokungurutswa pa laminate. Rutivi rwedhiramu rwe copper ruchaenderana nekuomarara kwedhiramu, nepo divi rakaonekwa richava rakaomarara.

Pepa remhangura rePCB rakaiswa paElectrode

Kugadzirwa kwemhangura yakachengetwa nemagetsi.

Kuti ishandiswe mukugadzirwa kwePCB kwakajairika, divi risina kusimba remhangura rinotanga rabatanidzwa negirazi-resin dielectric. Mhangura yasara yakaratidzwa (divi redhiramu) inofanira kusanganiswa nemaune nemakemikari (semuenzaniso, neplasma etching) isati yashandiswa mukugadzirwa kwelamination yemhangura yakavharirwa. Izvi zvichaita kuti ikwanise kusungirirwa kune rimwe divi rinotevera muPCB stackup.

Mhangura Yakaiswa Electrodeposited Pamusoro

Handizivi izwi rakanakisisa rinosanganisira marudzi ese akasiyana emishonga inorapwa pamusoromafoiri emhangura, saka musoro wenyaya uri pamusoro apa. Zvinhu izvi zvemhangura zvinozivikanwa zvikuru semafoiri akagadziriswa ne reverse, kunyange zvazvo kune dzimwe mhando mbiri dziripo (ona pazasi).

Mafoil akagadziriswa kumashure anoshandisa mushonga wepamusoro unoiswa parutivi rwakatsetseka (divi redhiramu) repepa remhangura rakaiswa electrodeposition. Rutivi rwekugadzirisa iganda rakatetepa rinoita kuti mhangura iome nemaune, saka rinonamatira zvakanyanya kune chinhu chinogadzirwa nemagetsi. Mishonga iyi inoshandawo sechidziviriro che oxidation chinodzivirira ngura. Kana mhangura iyi ikashandiswa kugadzira mapaneru e laminate, rutivi rwakagadzirwa runosungirirwa kune dielectric, uye rutivi rwakasara runoramba rwakavhurika. Rutivi rwakavhurika haruzodi mamwe magadzirirwo ekugadzirisa usati wacheka; runenge rwatova nesimba rakakwana rekubatanidza kune rinotevera divi muPCB stackup.

Misiyano mitatu iri papepa remhangura rakagadziriswa reverse inosanganisira:

Foiri yemhangura ine kurebesa kwekupisa kwakanyanya (HTE): Iyi foiri yemhangura ine electrodeposition inoenderana nezvinodiwa neIPC-4562 Grade 3. Chiso chayo chinoonekwa chinorapwawo ne oxidation barrier kudzivirira ngura panguva yekuchengetwa.

Foiri yakacheneswa kaviri: Mufoiri iyi yemhangura, mushonga wacho unoiswa kumativi ese efirimu. Izvi dzimwe nguva zvinonzi foiri yakacheneswa nedhiramu.

Mhangura inodzivisa: Iyi haiwanzo kuverengerwa semhangura yakagadziriswa pamusoro. Foil iyi yemhangura inoshandisa simbi pamusoro pemativi asina kusimba emhangura, iyo inozobva yaoma kusvika padanho rinodiwa.

Kushandiswa kwepurasitiki pamusoro pechinhu ichi chemhangura kuri nyore: foil inomonerwa kuburikidza nemabhati ekuwedzera e electrolyte anoisa jira rechipiri remhangura, oteverwa nejira rembeu rinodzivirira, uye pakupedzisira jira refirimu rinodzivirira kusviba.

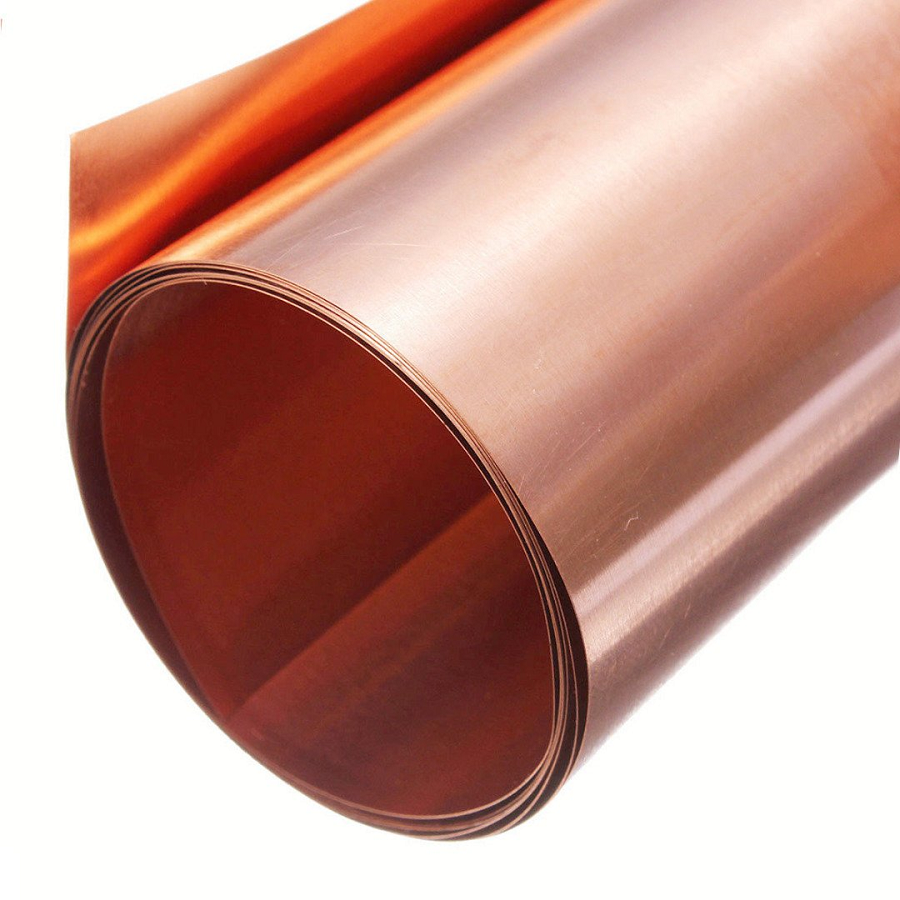

PCB foil yemhangura

Maitiro ekugadzirisa pamusoro pemafoil emhangura. [Chinobva: Pytel, Steven G., et al. "Kuongororwa kwekurapa kwemhangura uye mhedzisiro pakupararira kwemasaini." Muna 2008 58th Electronic Components and Technology Conference, mapeji 1144-1149. IEEE, 2008.]

Nemaitiro aya, une chinhu chinogona kushandiswa zviri nyore mukugadzirwa kwebhodhi kwakajairika pasina kuwedzera kwakanyanya.

Mhangura Yakamonerwa

Mafoil emhangura akamonerwa anopfuudza mupumburu wefoil yemhangura nepakati pemaroller maviri, ayo anotenderedza pepa remhangura nechando kusvika pakukora kwaunoda. Kuomarara kwepepa refoil rinozobuda kuchasiyana zvichienderana nematanho ekumonera (kumhanya, kumanikidzwa, nezvimwewo).

Pepa rinobuda rinogona kunge rakatsetseka, uye mitsetse inoonekwa pamusoro pepepa remhangura rakamonerwa. Mifananidzo iri pazasi inoratidza kuenzanisa pakati pepepa remhangura rakamonerwa neelectrodeposition nepepa rakamonerwa.

Kuenzanisa kwePCB copper foil

Kuenzanisa mafoil ane electrodepositioned vs. akaputirwa-akasungirirwa.

Mhangura Isina Mbiri Yakawanda

Iyi haisi mhando yefoil yemhangura yaungagadzira neimwe nzira. Mhangura isina chimiro chakaderera imhangura yakaiswa electrode inogadziriswa uye inogadziriswa ne micro-roughening process kuti ipe roughness yakaderera uye roughening yakakwana yekunamatira kune substrate. Maitiro ekugadzira foil idzi dzemhangura anowanzo kuve ega. Mafoil aya anowanzo kurongwa se ultra-low profile (ULP), very low profile (VLP), uye kungori low-profile (LP, inenge 1 micron average roughness).

Nyaya dzakabatana:

Sei Copper Foil ichishandiswa mukugadzira PCB?

Foiri yeCopper Inoshandiswa muPrinted Circuit Board

Nguva yekutumira: Chikumi-16-2022