Foyi yemhanguraine mwero wakaderera weokisijeni pamusoro uye inogona kubatanidzwa nezvinhu zvakasiyana-siyana, zvakaita sesimbi, zvinhu zvinodzivirira kupisa. Uye foil yemhangura inonyanya kushandiswa mukudzivirira electromagnetic uye antistatic. Kuti iise foil yemhangura inofambisa mhepo pamusoro pe substrate uye isanganiswe ne substrate yesimbi, ichapa kuenderera mberi kwakanaka uye kudzivirira electromagnetic. Inogona kukamurwa kuita: foil yemhangura inonamira yoga, foil yemhangura yerutivi rumwe, foil yemhangura yerutivi ruviri nezvimwe zvakadaro.

Muchikamu chino, kana muchida kudzidza zvakawanda nezve copper foil mukugadzirwa kwePCB, ndapota tarisai uye verengai zviri pazasi muchikamu chino kuti muwane rumwe ruzivo rwehunyanzvi.

Ndezvipi zvinhu zvinowanikwa mufoiri yemhangura mukugadzirwa kwePCB?

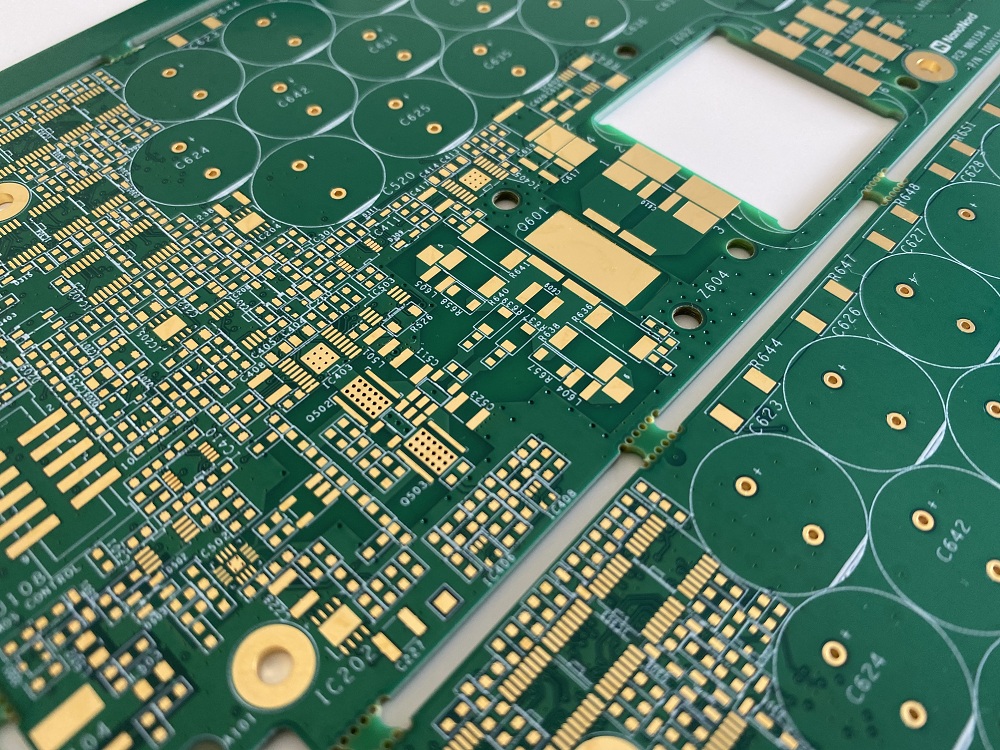

PCB foil yemhangurandiyo ukobvu hwekutanga hwemhangura hunoiswa pazvikamu zvekunze nemukati zvebhodhi rePCB rine zvikamu zvakawanda. Kurema kwemhangura kunotsanangurwa sehuremu (mumaounces) hwemhangura huripo munzvimbo imwe chete ye square foot yenzvimbo. Iyi parameter inoratidza ukobvu hwese hwemhangura pachikamu chacho. MADPCB inoshandisa zviyero zvemhangura zvinotevera pakugadzira PCB (pre-plate). Kurema kunoyerwa mu oz/ft2. Kurema kwemhangura kwakakodzera kunogona kusarudzwa kuti kuenderane nezvinodiwa pakugadzira.

· Mukugadzirwa kwePCB, mafoil emhangura ari mumarolls, ayo ari emagetsi ane kuchena kwe99.7%, uye ukobvu hwe1/3oz/ft2 (12μm kana 0.47mil) – 2oz/ft2 (70μm kana 2.8mil).

· Foil yemhangura ine mwero wakaderera weokisijeni yepamusoro uye inogona kunamirwa kare nevagadziri vema laminate kune zvakasiyana-siyana zvebase, zvakaita sesimbi core, polyimide, FR-4, PTFE uye ceramic, kuti igadzire ma laminates ane copper clad.

· Inogonawo kuiswa mubhodhi rine zvidimbu zvakawanda sefoiri yemhangura pachayo usati wadzvanya.

· Mukugadzirwa kwemaPCB echinyakare, ukobvu hwekupedzisira hwemhangura pazvikamu zvemukati hunosara hwefoil yekutanga yemhangura; Pazvikamu zvekunze tinoisa mhangura yakawedzerwa ye18-30μm pamatanho panguva yekuputira panel.

· Mhangura yemapuranga ekunze emapuranga ane layer yakawanda iri muchimiro che copper foil uye yakamanikidzwa pamwe chete ne prepregs kana cores. Kuti ishandiswe ne microvias mu HDI PCB, copper foil iri zvakananga pa RCC (resin coated copper).

Sei foil yemhangura ichidiwa mukugadzirwa kwePCB?

Foiri yemhangura yemagetsi (yakachena kupfuura 99.7%, ukobvu 5um-105um) ndeimwe yezvinhu zvakakosha muindasitiri yemagetsi. Kufambira mberi nekukurumidza kweindasitiri yeruzivo rwemagetsi, kushandiswa kwefoiri yemhangura yemagetsi kuri kukura, zvigadzirwa zvinoshandiswa zvakanyanya mumakarukureta emaindasitiri, Midziyo yekutaurirana, Midziyo yeQA, mabhatiri e-lithium-ion, materevhizheni ehurumende, marekodhi evhidhiyo, maCD player, makopi, nharembozha, air conditioning, mota dzemagetsi, mitambo yekutamba.

Foiri yemhangura yeindasitiriinogona kukamurwa kuita mapoka maviri: jira remhangura rakamonerwa (RA copper foil) uye jira remhangura repoindi (ED copper foil), umo jira remhangura rinoita calendar rine ductility yakanaka nezvimwe zvinhu, ndiyo nzira yekutanga yeplate yakapfava inoshandiswa Copper foil, nepo jira remhangura re electrolytic riri mutengo wakaderera wekugadzira jira remhangura. Sezvo jira remhangura rinomonerwa riri chinhu chakakosha chebhodhi rakapfava, saka hunhu hwejira remhangura rinoita calendar uye shanduko yemitengo muindasitiri yebhodhi rakapfava zvine simba rakati.

Ndeipi mitemo yekutanga yekugadzira foil yemhangura muPCB?

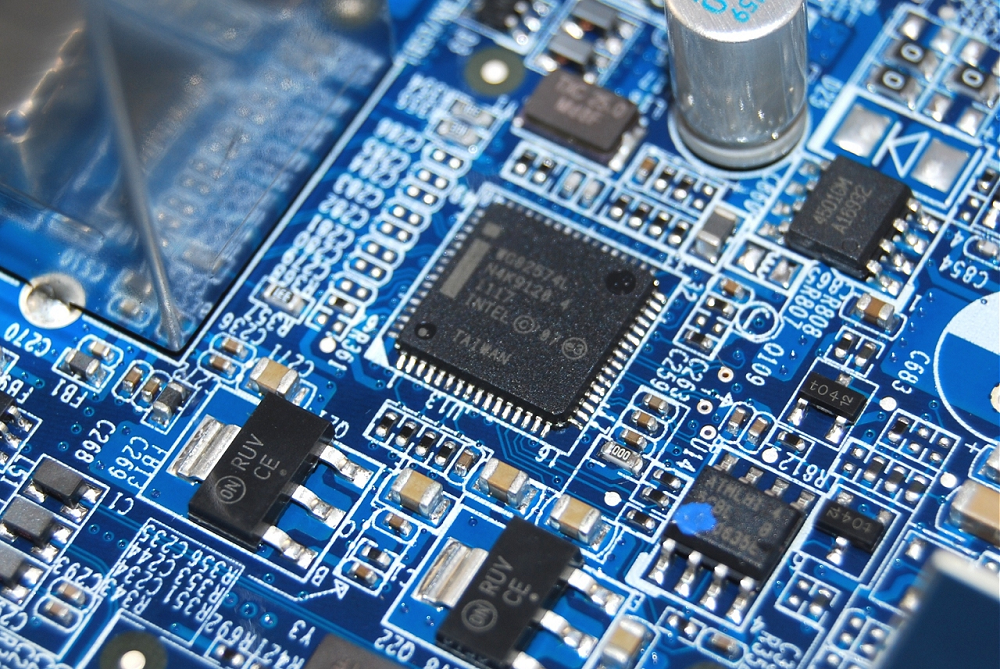

Unoziva here kuti mabhodhi emagetsi akadhindwa anowanikwa zvakanyanya muboka remagetsi? Ndine chokwadi chekuti pane rimwe riri mumudziyo wemagetsi wauri kushandisa izvozvi. Zvisinei, kushandisa michina iyi yemagetsi usinganzwisise tekinoroji yavo uye nzira yekugadzira itsika yakajairika. Vanhu vari kushandisa michina yemagetsi awa imwe neimwe asi havazivi kuti inoshanda sei. Saka heano mamwe maPCB anotaurwa kuti ane kunzwisisa nekukurumidza mashandiro anoita mabhodhi emagetsi akadhindwa.

· Bhodhi redunhu rakadhindwa ibhodhi repurasitiki rakareruka rine girazi. Foil yemhangura inoshandiswa kuronda nzira uye inobvumira kufamba kwechaji nemasaini mukati memudziyo. Matrace emhangura ndiyo nzira yekupa simba kuzvikamu zvakasiyana zvemudziyo wemagetsi. Panzvimbo pewaya, matrace emhangura anotungamira kufamba kwechaji muPCBs.

· MaPCB anogona kuva jira rimwe chete uye maviri zvakare. PCB imwe chete ine jira ndiyo iri nyore. Ane jira remhangura kune rumwe rutivi uye rimwe divi ndiro nzvimbo yezvimwe zvikamu. Paanenge ari paPCB ine jira mbiri, mativi ese akachengeterwa jira remhangura. MaPCB akaomarara ane jira mbiri ane zviratidzo zvakaoma zvekuyerera kwechaja. Hapana jira remhangura rinogona kuyambukana. MaPCB aya anodiwa pamidziyo yemagetsi inorema.

· Kunewo zvidimbu zviviri zvezvisundiro uye silkscreen paPCB yemhangura. Chifukidzo chesolder chinoshandiswa kusiyanisa ruvara rwePCB. Kune mavara akawanda ePCB anowanikwa akadai segirini, pepuru, tsvuku, nezvimwewo. Chifukidzo chesolder chinotsanangurawo mhangura kubva kune dzimwe simbi kuti tinzwisise kuoma kwekubatana. Kunyange zvazvo silkscreen iri chikamu chechinyorwa chePCB, mavara akasiyana nenhamba zvinonyorwa pasilkscreen yemushandisi neinjiniya.

Ungasarudza sei zvinhu zvakakodzera zve copper foil mu PCB?

Sezvambotaurwa, unofanira kuona nzira yekunzwisisa maitiro ekugadzira bhodhi redunhu rakadhindwa. Magadzirirwo emabhodhi aya ane zvikamu zvakasiyana. Ngatinzwisise izvi nekutevera:

Zvinhu zvepasi pevhu:

Hwaro hwepasi pamusoro pebhodhi repurasitiki rinosungirirwa negirazi ndiro substrate. Substrate chimiro che dielectric chepepa rinowanzo gadzirwa nema epoxy resins nepepa regirazi. Substrate yakagadzirwa nenzira yekuti ikwanise kusangana nezvinodiwa semuenzaniso transition temperature (TG).

Kuravira:

Sezvinoratidzwa nezita racho, lamination inzira yekuwanawo hunhu hunodiwa senge thermal expansion, shear strength, uye transition heat (TG). Lamination inoitwa pasi pekumanikidzwa kwakanyanya. Lamination uye substrate pamwe chete zvinoita basa rakakosha mukuyerera kwemagetsi muPCB.

Nguva yekutumira: Chikumi-02-2022