Copper foiline yakaderera mwero weokisijeni yepamusoro uye inogona kusungirirwa neakasiyana akasiyana ma substrates, akadai sesimbi, insulating zvinhu.Uye foil yemhangura inonyanya kuiswa mumagetsi ekudzivirira uye antistatic.Kuisa iyo conductive mhangura foil pane substrate pamusoro uye yakasanganiswa nesimbi substrate, ichapa kuenderera kwakanakisa uye electromagnetic kudzivirira.Inogona kukamurwa kuita: yekuzvinamira yemhangura foil, single side foil yemhangura, kaviri side foil yemhangura nezvimwe zvakadaro.

Mundima iyi, kana iwe uchizodzidza zvakawanda nezve copper foil muPCB kugadzira maitiro, ndapota tarisa uye uverenge zviri pazasi mundima iyi kuti uwane rumwe ruzivo rwehunyanzvi.

Ndezvipi zvinhu zvemhangura foil mukugadzira PCB?

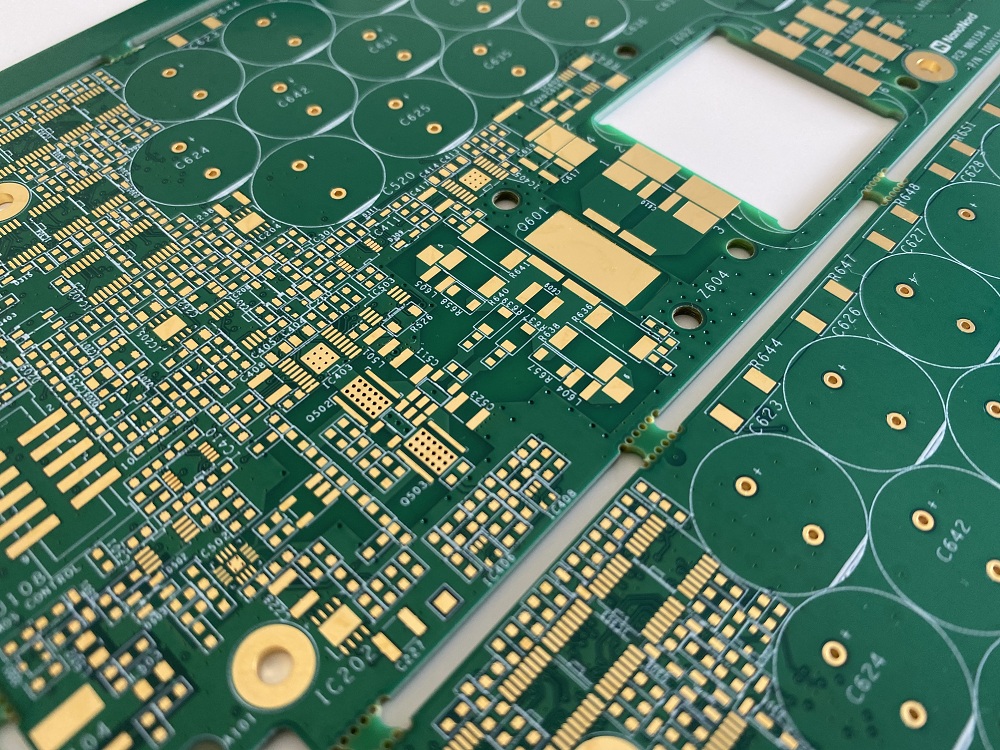

PCB yemhangura foilndiko kwekutanga ukobvu hwemhangura hunoshandiswa pamitsetse yekunze neyemukati yebhodhi rePCB rakawanda.Huremu hwemhangura hunotsanangurwa sehuremu (mumaounces) emhangura iripo mune imwe square foot yenzvimbo.Iyi parameter inoratidza kukora kwemhangura padandemutande.MADPCB inoshandisa huremu hwemhangura hunotevera hwekugadzira PCB (pre-plate).Huremu hwakayerwa neoz/ft2.Huremu hwakakodzera hwemhangura hunogona kusarudzwa kuti huenderane nezvinodiwa zvekugadzira.

· Mukugadzirwa kwePCB, mapepa emhangura ari mumapumburu, ari egiredhi remagetsi nekuchena kwe99.7%, uye ukobvu hwe1/3oz/ft2 (12μm kana 0.47mil) – 2oz/ft2 (70μm kana 2.8mil).

· Copper foil ine yakaderera mwero weokisijeni yepamusoro uye inogona kufanonamirwa nevagadziri velaminate kune zvakasiyana-siyana zvekushandisa, sesimbi core, polyimide, FR-4, PTFE uye ceramic, kugadzira copper clad laminates.

· Iyo zvakare inogona kuunzwa mu multilayer board semhangura foil pachayo isati yadzvanya.

· Mukugadzirwa kwePCB kwakajairwa, ukobvu hwemhangura hwekupedzisira hwemukati hunoramba huri hwekutanga foil yemhangura;Pamatanho ekunze tinoisa yakawedzera 18-30μm mhangura pamakwara panguva yekugadzira mapaneru.

· Mhangura yemapuranga ekunze emapuranga akawanda ari muchimiro chemhangura foil uye yakamanikidzwa pamwe chete ne prepregs kana cores.Kuti ishandiswe nemamicrovias muHDI PCB, foil yemhangura iri paRCC (resin coated copper).

Nei foil yemhangura ichidikanwa mukugadzira PCB?

Electronic giredhi yemhangura foil (kuchena kweanopfuura 99.7%, ukobvu 5um-105um) ndechimwe chezvinhu zvakakosha zveindasitiri yemagetsi Kukurumidza kukura kweindasitiri yeruzivo rwemagetsi, kushandiswa kwemagetsi giredhi yemhangura foil iri kukura, zvigadzirwa zviri kushandiswa zvakanyanya. mumaindasitiri macalculator, Communications equipment, QA equipment, lithium-ion batteries, civilian television sets, video recorder, CD player, makopi, runhare, air conditioning, mota dzemagetsi, game consoles.

Industrial copper foilinogona kupatsanurwa muzvikamu zviviri: yakakungurutswa yemhangura foil (RA yemhangura foil) uye point yemhangura foil (ED copper foil), umo iyo kalendari yemhangura foil ine yakanaka ductility uye humwe hunhu, ndiyo yekutanga nyoro plate process inoshandiswa Copper foil, nepo iyo electrolytic copper foil mutengo wakaderera wekugadzira foil yemhangura.Sezvo iyo inotenderedza foil yemhangura yakakosha zvinhu zvebhodhi rakapfava, saka hunhu hwekarenda yemhangura foil uye shanduko yemutengo pane yakapfava board indasitiri ine imwe mhedzisiro.

Ndeipi mitemo yekutanga yekugadzira yemhangura foil muPCB?

Unoziva here kuti mabhodhi edunhu akadhindwa akajairika muboka remagetsi?Ndine chokwadi chekuti imwe iripo mumudziyo wemagetsi wauri kushandisa izvozvi.Nekudaro, kushandisa izvi zvigadzirwa zvemagetsi pasina kunzwisisa tekinoroji yavo uye nzira yekugadzira zvakare yakajairika tsika.Vanhu vari kushandisa midziyo yemagetsi paawa imwe neimwe asi havazivi kuti inoshanda sei.Saka hezvino zvimwe zvikamu zvikuru zvePCB zvinotaurwa kuti zvine kukurumidza kunzwisisa kuti mapuranga edunhu akadhindwa anoshanda sei.

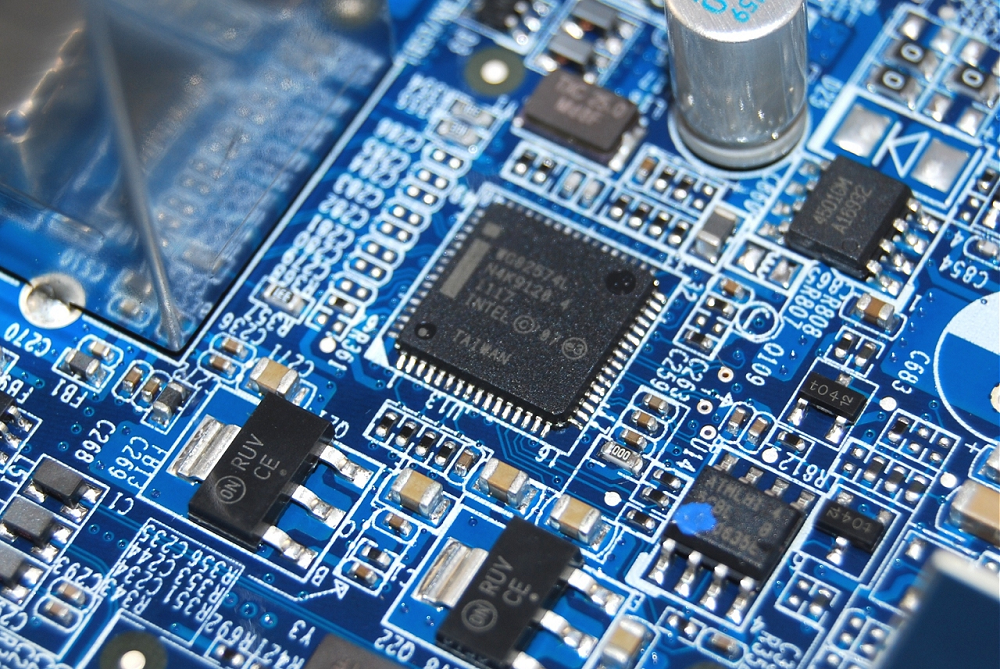

· Iyo yakadhindwa yedunhu bhodhi iri nyore mapuranga epurasitiki pamwe nekuwedzera kwegirazi.Iyo foil yemhangura inoshandiswa kutsvaga nzira uye inobvumira kuyerera kwemachaji uye masaini mukati memudziyo.Nzira dzemhangura ndiyo nzira yekupa simba kune zvikamu zvakasiyana zvechigadzirwa chemagetsi.Panzvimbo pewaya, mitsetse yemhangura inotungamira kuyerera kwechaji mumaPCB.

· MaPCB anogona kuve akaturikidzana uye maviri akaturikidzana zvakare.Imwe yakaturikidzana PCB ndiyo iri nyore.Vane foiling yemhangura kune rumwe rutivi uye rumwe rutivi ikamuri yezvimwe zvikamu.Ndichiri paPCB yakapetwa kaviri, mativi ese ari maviri akachengeterwa foiling yemhangura.Akapetwa kaviri ndiwo maPCB akaomarara ane mitsetse yakaoma yekuyerera kwechaji.Hapana mapepa emhangura anogona kuyambuka mumwe nemumwe.Aya maPCB anodiwa kune zvinorema zvemagetsi zvishandiso.

· Kune zvakare maviri akaturikidzana emasoja uye silkscreen paPCB yemhangura.A solder mask inoshandiswa kusiyanisa ruvara rwePCB.Kune akawanda mavara ePCB anowanikwa akadai segirini, yepepuru, tsvuku, etc. Solder mask inotsanangurawo mhangura kubva kune dzimwe simbi kuti unzwisise kuoma kwekubatanidza.Nepo silkscreen iri chikamu chezvinyorwa zvePCB, mavara akasiyana uye manhamba akanyorwa pasirikikirini yemushandisi uye mainjiniya.

Maitiro ekusarudza akakodzera zvinhu zvemhangura foil muPCB?

Sezvambotaurwa, iwe unofanirwa kuona nhanho-ne-nhanho nzira yekunzwisisa maitiro ekugadzira yeakadhindwa redunhu bhodhi.Zvigadzirwa zvemapuranga aya zvine zvidimbu zvakasiyana.Ngatinzwisise izvi nekutevedzana:

Substrate zvinhu:

Nheyo yehwaro pamusoro pepurasitiki bhodhi yakasimbiswa negirazi ndiyo substrate.A substrate chimiro che dielectric chepepa rinowanzo gadzirwa ne epoxy resins uye girazi bepa.A substrate yakagadzirwa nenzira yekuti inogona kusangana nezvinodiwa semuenzaniso shanduko yekushisa (TG).

Lamination:

Sezvakajeka kubva pazita, lamination zvakare inzira yekuwana inodiwa zvivakwa senge thermal kuwedzera, shear simba, uye shanduko kupisa (TG).Lamination inoitwa pasi pekumanikidzwa kwakanyanya.Lamination uye substrate pamwechete inoita basa rakakosha mukuyerera kwemagetsi machaji muPCB.

Nguva yekutumira: Jun-02-2022